AUTOMATION & AI FOR YOUR SMARTPHONE PROCESSING

Next-generation robotics for high-speed grading and repair. Remove the human bottleneck and start scaling your business.

OUR SOLUTIONS

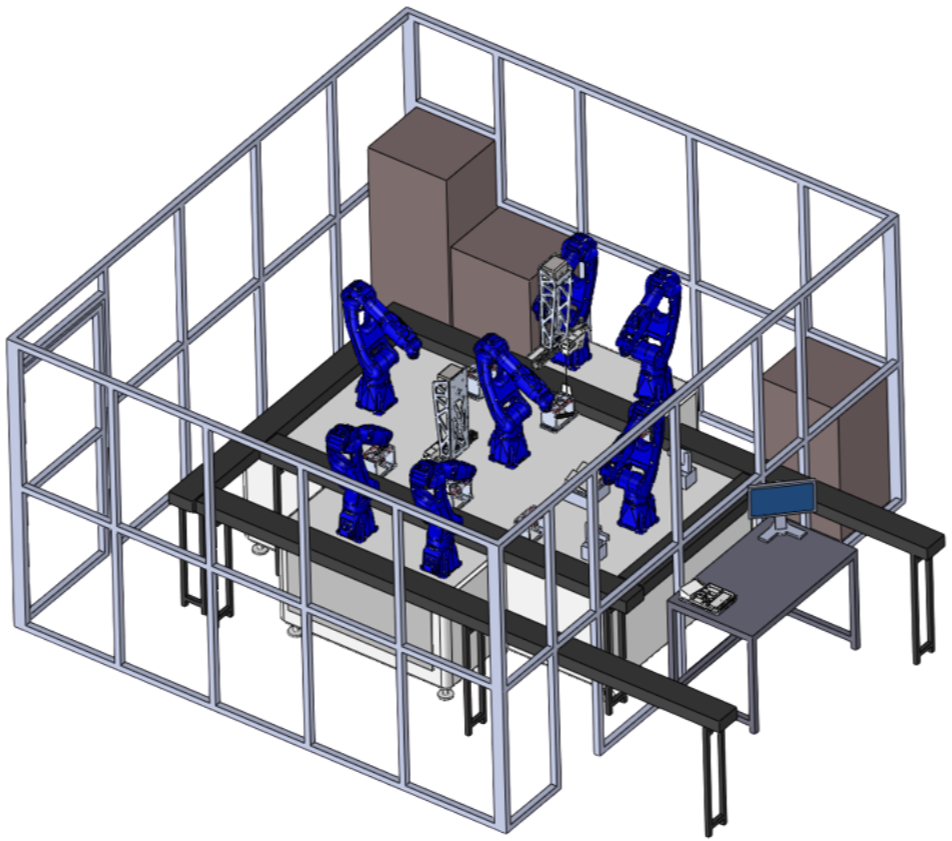

BOBEE

Automated smartphone repair

GRADBOX

Automated smartphone grading

FAQs

-

BoBee is made for industrial use. It can handle from thousands to hundreds of thousands of phones a month. Built in modular blocks, you can scale as your volume grows.

-

The GradBox has been specifically designed for both retail and industry. You can set it up in your stores or automate it in your industrial sites.

-

While the BoBee solution is more disruptive, we guide you through the entire implementation to ensure a smooth, fast transition. The GradBox is plug-and-play and can be set up quickly with minimal disruption.

OUR STORY

Built by refurbishers, for refurbishers

2015- PRESENT

The journey began in in Vendée, France, with the founding of Cash and Repair, a specialist network dedicated to the repair and buyback of high-tech products. Over a decade of growth, this network expanded into 40 active locations, establishing itself as the 3rd largest repair network in France. By completing over 1 million repairs, we didn't just gain experience; we gathered the real-world data necessary to understand exactly where manual processes fail at scale.

2021- PRESENT

In 2021, we launched our own refurbished brand, BeeMyPhone, to set a new standard for quality in the consumer market. Operating our own brand forced us to confront the ultimate industry bottleneck: the inherent subjectivity of human grading. We realized that to protect our margins and eliminate return rates, we needed a level of consistency that manual labor simply could not provide. This internal demand for perfection became the driving force behind our shift toward automation.

2019- PRESENT

BoBee Robotics is the culmination of 7 years of intensive R&D and a deep internalization of robotics, mechanical engineering, and AI expertise. We are the first users of our own BoBee and GradBox solutions, having designed these machines specifically to solve the scalability issues we faced within our own ecosystem. Today, we provide a 360° industry expertise that allows any facility to transition from a labor-intensive workshop to a high-output, next-generation robotic solutions.

They Support Our Innovation